Fashion is an industry defined by innovation, speed, and self-expression. As technology continues to evolve, so does the way clothing and textiles are designed, manufactured, and delivered. Among the most transformative advancements in recent years is the emergence of Direct to Fabric Digital Textile Printers, also known as Direct Printers. These high-tech machines are not only revolutionizing textile production but are also setting the stage for a more sustainable, creative, and agile future in fashion.

This article explores why Direct to Fabric Digital Textile Printers are rapidly becoming indispensable tools in the fashion world and why their influence is only expected to grow.

What Are Direct to Fabric Digital Textile Printers?

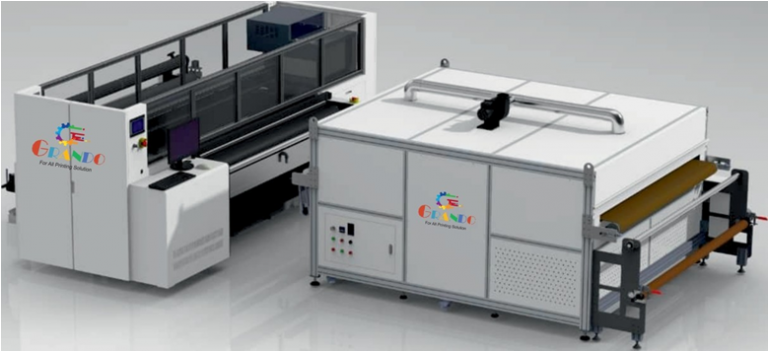

A Direct to Fabric Digital Printer is a type of digital printer that applies designs directly onto fabrics using inkjet technology. Unlike traditional printing methods, these printers require no transfer paper or screens. Instead, they use specialized textile inks (such as pigment, reactive, or disperse inks) to deliver vibrant, detailed prints directly onto natural or synthetic fabrics.

Customization at Scale

One of the most powerful features of Direct Printers is their ability to enable mass customization. Today’s consumers want personalized fashion—unique pieces that reflect their identity. With Direct to Fabric Digital Textile Printers:

-

Designers can easily create limited-edition prints.

-

Custom orders can be fulfilled with short turnaround times.

-

Made-to-order production becomes feasible and profitable.

This capability is a game-changer for independent designers, small businesses, and even large brands looking to cater to niche markets.

Speed and Agility in Production

In the fast-paced world of fashion, speed matters. Direct Printers eliminate the need for time-consuming screen setups or dyeing processes, drastically reducing the lead time from concept to final product. Whether you're printing prototypes or full runs, these printers allow for:

-

Faster prototyping and sampling

-

Immediate design adjustments

-

On-demand production without minimum order constraints

This kind of agility is essential for fashion brands trying to stay ahead of trends.

Reducing Environmental Impact

Sustainability is no longer optional—it's a necessity. The fashion industry is notorious for its environmental footprint, with traditional textile dyeing and printing contributing significantly to water pollution and waste. In contrast, Direct to Fabric Digital Textile Printers offer a more eco-friendly alternative:

-

Waterless printing processes

-

Low energy consumption

-

Minimal waste due to precise ink application

-

Eco-friendly, water-based inks

This makes them an ideal choice for fashion brands committed to reducing their environmental impact and meeting regulatory standards.

Superior Print Quality

Fashion relies heavily on aesthetics, and nothing short of exceptional print quality will do. Direct Printers offer:

-

High-resolution prints with fine details

-

Rich, vibrant colors that remain consistent

-

Excellent wash and rub fastness

The ability to produce such high-quality results gives designers the freedom to experiment with intricate patterns, gradients, and textures that were once difficult to achieve with traditional methods.

Fabric Versatility

Direct to Fabric Digital Textile Printers can handle a wide range of textiles, including:

-

Cotton

-

Silk

-

Wool

-

Polyester

-

Blended fabrics

This versatility allows fashion designers to work across various product categories—from casual wear and high fashion to accessories and home décor—all using the same core printing technology.

Cost Efficiency

While the initial investment in Direct Printers can be significant, the long-term cost savings are compelling:

-

No need for screens or plates

-

Reduced labor costs

-

Less fabric waste

-

Efficient ink usage

For small-batch or on-demand production, Direct Printers offer an economical alternative to traditional methods that often involve higher setup and material costs.

Enabling Local and Ethical Production

By making on-demand and small-batch production viable, Direct Printers empower brands to produce locally rather than outsourcing to far-off factories. This shift:

-

Shortens the supply chain

-

Increases transparency

-

Enhances ethical labor practices

-

Supports local economies

As consumers become more socially conscious, brands using local, ethical production models gain a competitive edge.

Design Freedom and Innovation

Digital textile printing unleashes a new level of design creativity. With Direct to Fabric Digital Textile Printers:

-

Designers can print photographic images, hand-drawn sketches, and digital illustrations with equal ease.

-

Designs can be adjusted on the fly.

-

Creative experimentation is encouraged due to low setup costs.

This design freedom is particularly appealing in a market that values innovation and uniqueness.

Future-Proofing Fashion Businesses

As trends shift and technology evolves, fashion brands must adapt or fall behind. Investing in Direct Printers is a forward-thinking strategy that prepares businesses for:

-

Rising demand for personalization

-

Eco-conscious consumer behavior

-

Rapid design-to-market cycles

-

Technological integration with AI and automation

Real-World Applications and Case Studies

-

Luxury brands are using direct printing to create exclusive prints for seasonal collections.

-

Streetwear designers use it for limited runs that sell out quickly.

-

Custom apparel businesses rely on direct printers to offer personalized t-shirts, scarves, and dresses.

These case studies underscore the versatility and practical benefits of direct printing in diverse fashion segments.

Choosing the Right Direct Printer

When selecting a Direct to Fabric Digital Textile Printer, consider:

-

Fabric compatibility

-

Print resolution and speed

-

Ink types and drying/fixation methods

-

Software support and user interface

-

Maintenance requirements

Conclusion

The future of fashion is digital, sustainable, and personalized—and Direct to Fabric Digital Textile Printers are at the heart of this transformation. These powerful machines offer unmatched benefits in speed, quality, sustainability, and creative freedom, making themhe potential of this technology and redefine what’s possible in textile design and fashion production. essential tools for fashion brands ready to embrace the future.